Uncomplicated Heavy-Weight Dimension with Modern Industrial Scales

Uncomplicated Heavy-Weight Dimension with Modern Industrial Scales

Blog Article

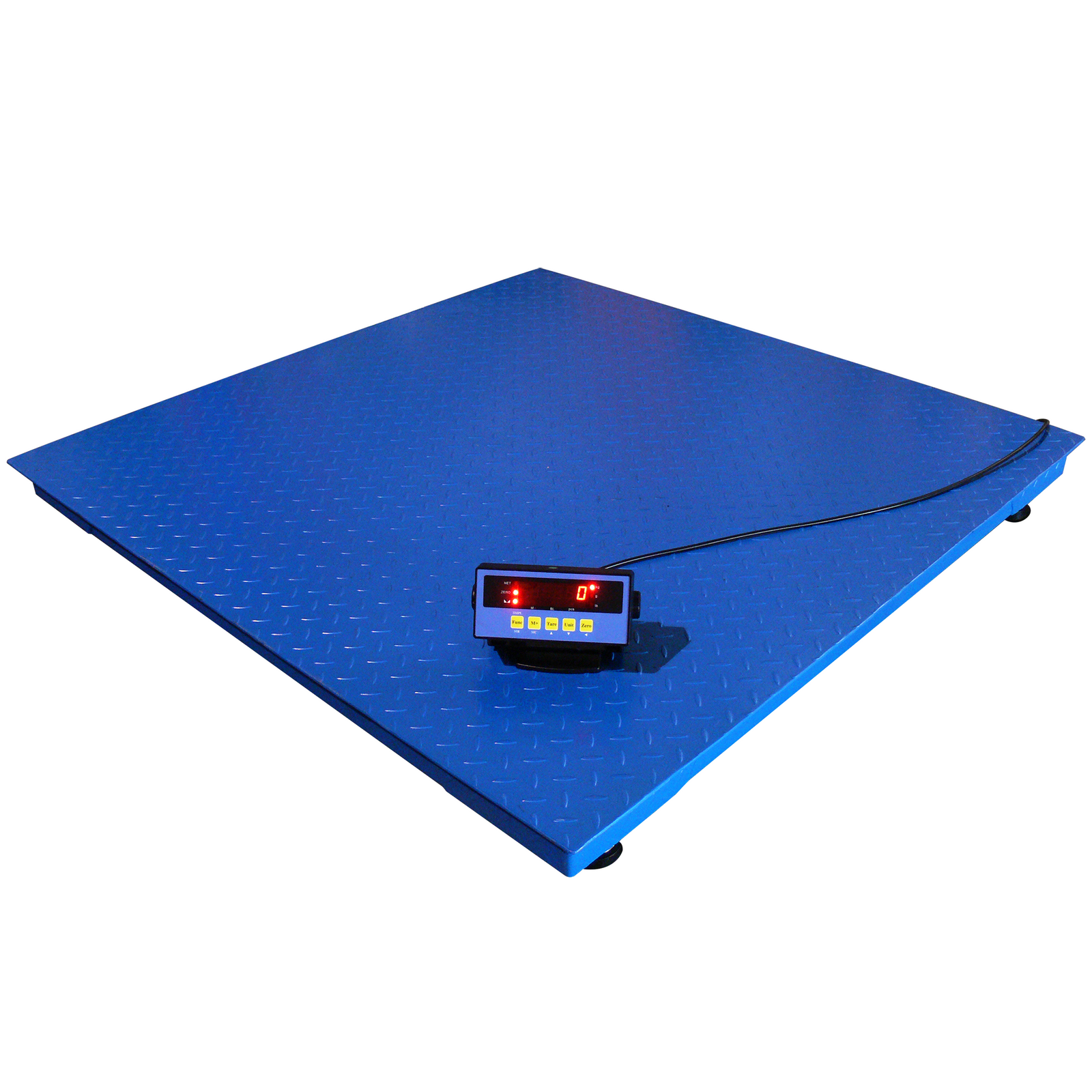

Leading Attributes to Search For in High-Quality Industrial Scales

In the world of industrial operations, picking the right range is vital for guaranteeing performance and precision. Key attributes such as precision and precision, in addition to durability and build top quality, play a significant function in determining the viability of a range for certain applications. Furthermore, considerations like load capability, ease of use, and connection options better boost functional performance. Recognizing these elements is necessary for making an informed decision, yet many organizations forget essential facets that can impact their productivity. A closer exam of these features exposes insights that can change commercial considering methods.

Accuracy and Precision

Making certain the precision and precision of commercial scales is paramount for reliable operations across various sectors. Exact dimensions are essential in industries such as manufacturing, logistics, and food processing, where even minor inconsistencies can cause substantial economic losses, compromised item high quality, or regulatory non-compliance. Premium commercial scales are developed to deliver trusted efficiency, making use of innovative technology to ensure exact weight readings.

The calibration process is necessary in preserving the precision of these ranges. Normal calibration against accredited referral weights guarantees that any kind of drift in dimension is remedied, thereby upholding compliance with market standards. Furthermore, using high-resolution tons cells enhances the scale's capacity to find minute weight changes, even more boosting its accuracy.

Longevity and Build Quality

Resilience and develop top quality are essential aspects that figure out the long life and reliability of commercial scales sought after environments. Industrial ranges are usually based on rough problems, including direct exposure to dust, moisture, and heavy lots. The products used in their construction play a crucial role in ensuring they can hold up against these challenges.

High-quality industrial ranges normally include robust housings made from materials such as stainless steel or light weight aluminum, which not only provide architectural stability but likewise stand up to deterioration and wear. In addition, focus to detail in the style, such as enhanced edges and shock-absorbent feet, can improve durability and secure sensitive elements from damages.

Furthermore, high-grade parts, including tons cells and digital parts, contribute to the total construct high quality. These parts ought to be developed to endure temperature fluctuations and resonances typically discovered in commercial settings. Making sure appropriate ingress security (IP rating) is additionally necessary, as it shows the scale's ability to stand up to dirt and liquid exposure.

Eventually, picking commercial scales with superior sturdiness and build top quality will result in a much more trusted, lasting remedy that fulfills the extensive needs of different commercial applications.

Lots Ability and Array

When picking industrial scales, understanding their tons ability and variety is crucial for conference specific functional needs. Lots ability describes the maximum weight that a range can precisely gauge, while the array shows the range of weights the range can take care of effectively. It is crucial to pick a range that not just satisfies present needs however also fits possible future demands.

Various markets have distinct their explanation weight dimension needs. A production facility might need scales qualified of weighing heavy equipment parts, while a research laboratory may just require scales for lighter materials. Picking a range with a suitable lots capacity makes certain precision and precision, stopping overloading that can bring about equipment damages or inaccurate readings.

A range that can determine both hefty and light weights precisely can boost functional performance, allowing for flexible applications. Spending in ranges with appropriate tons ability and range substantially contributes to performance, compliance with industry criteria, and overall operational dependability.

Convenience of Usage and Upkeep

Along with user-friendliness, convenience of maintenance is one more critical facet to take into consideration. Ranges that are developed with available parts assist in routine maintenance jobs such as calibration, battery, and cleaning substitute. A modular style can additionally simplify these procedures, enabling quick repair work and very little downtime.

Furthermore, the materials utilized in the building of commercial ranges play a substantial function in maintenance. Ranges made from long lasting, corrosion-resistant materials are easier to clean and less vulnerable to damage, which expands their life expectancy and decreases general operational expenses.

Normal maintenance schedules, led by the maker's suggestions, are necessary for making sure optimum performance. By prioritizing simplicity of use and maintenance, companies can make sure that their commercial ranges continue to be informative post effective, trustworthy, and efficient devices in their operations. This brings about improved productivity and an extra effective process.

Connection and Integration Options

Integrating commercial scales into existing functional frameworks is substantially improved by robust connection alternatives. Top quality commercial ranges ought to provide multiple connectivity approaches, including USB, Ethernet, and cordless alternatives such as Wi-Fi or Bluetooth. These attributes assist in seamless information transfer to main databases, ERP systems, or cloud platforms, making it possible for real-time tracking and coverage.

In addition, progressed combination choices enable compatibility with existing equipment, such as printers or barcode scanners, streamlining processes and boosting operations efficiency. Scales that support industry-standard protocols, such as Modbus or RS-232, can conveniently communicate with numerous devices and systems, making certain a natural operational environment.

One more important aspect is the capacity to integrate with software program options that evaluate and visualize data - Industrial Scales. Scales outfitted with APIs or software application development packages (SDKs) provide businesses the versatility to tailor capabilities tailored to their specific demands

Lastly, thinking about future scalability is vital; choosing scales that can adjust to evolving technological developments ensures long-lasting value and reduces the need for pricey replacements. In summary, evaluating connection and combination choices is crucial when picking top quality industrial scales that will boost functional performance and data administration.

Verdict

In verdict, choosing premium industrial scales necessitates careful factor to consider of a number of vital features. Industrial Scales. Focusing on these qualities ultimately leads to boosted efficiency and long-lasting value in commercial applications, strengthening the significance of informed decision-making in range selection.

In the world of commercial operations, picking the right range is critical for making sure performance and accuracy.Making sure the accuracy and accuracy of industrial scales look here is vital for effective procedures throughout different fields. Tons capacity refers to the maximum weight that a range can accurately gauge, while the range suggests the spectrum of weights the range can deal with properly. A manufacturing center might require ranges qualified of considering heavy machinery elements, while a research laboratory may only need scales for lighter materials. By prioritizing convenience of use and upkeep, services can guarantee that their commercial ranges remain effective, dependable, and reliable devices in their operations.

Report this page